Stamping Tooling Optimization

Stamping Tooling Optimization addresses the need to fully realize the benefits of AHSS, which depends upon the ability to aggressively form, trim and pierce these steels into complex geometries needed for automotive applications. The goal of this project team is to determine cost-effective and durable die materials, surface treatments, coatings and die designs for stamping AHSS by developing and implementing tests that simulate die tool environments and failure modes.

Auto/Steel Partnership is investing in die wear research. A sliding wear test machine was recently commissioned by Dr. X. Nie of University of Windsor. This new equipment will enable continuous improvement of die materials, surface treatments and coatings.

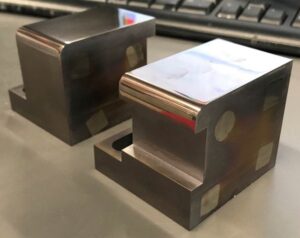

A/SP is exploring the capabilities and limitations of metal additive manufacturing as a fabrication method for small die inserts such as flange steels, trim steels, restrike steels, etc. Pictured below is the 3D printed insert that was installed in a prog die and runoff at the supplier. A 50k hit forming trial is planned to study the durability of these inserts.

Resources: Training & Publications

Training

Publications

- 2025 GDIS Presentations

- 2024 GDIS Presentations

- 2023 GDIS Presentations

- 2022 GDIS Presentations

- 2021 GDIS Presentations

- Development of Tabletop Sliding Tribometer for Tooling Optimization

- Repairability of 3rd Gen AHSS

- Anti-Wear Improvement of Stamping Die Materials Through Duplex Chroming

- Evaluation of Die Wear with Stamping DP1180 Steel

- Impact-Sliding Wear Tests on Duplex-Treated Die Materials

- Coating Impact Fatigue Test – Phase II

- Procedures for Testing Characteristics of Automotive Sheet Steel Lubricants